Industrial Automation

- Date:2018-12-19 18:16

Background

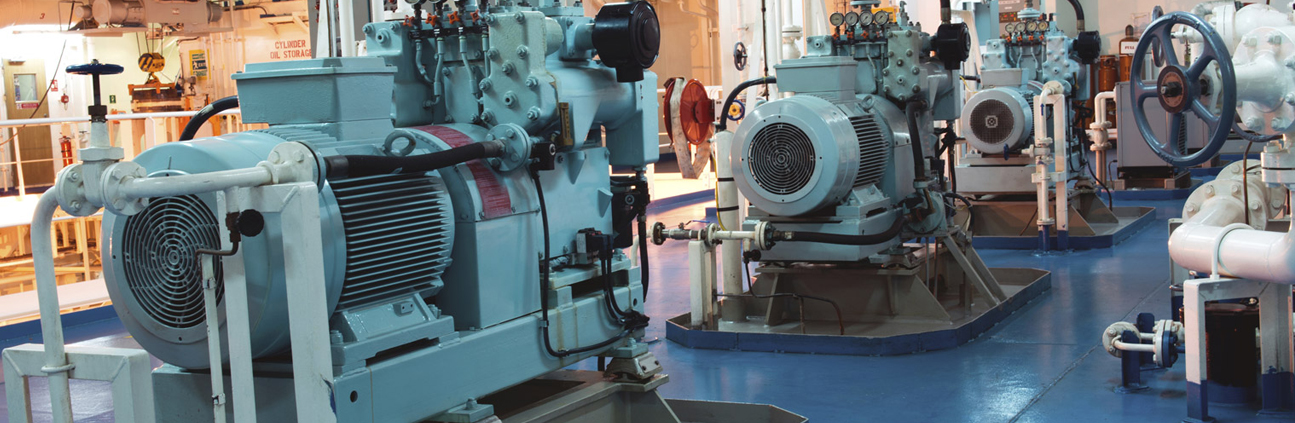

Air compressor is widely used in different kinds of industry and after long time deployment, machines maintenance had become critically important because if you do not have remote access to the air compressor and provide routine maintenance, then it would be too late if it finally shut down totally. That’s a huge losses to the customers and finding a suitable solution for remote maintenance would be the consideration topics of the air compressor manufacturer.

Project Technical Highlights

- The router need to be 3G HSPA+ and with Dual SIM design in order to allow the customer to use wo operators’s services.

- The router should be industrial design that be able to conquer the harsh environment like strong vibration

and static attack during the operation.

- The router should be able to work under high temperature, could be -20 to 75 degrees, that’s a big challenge.

- The router should have abundant connection in order to get all the things connected and be remotely configured.

Solution

NavigateWorx NR500-S3G provide the remote connection between the remote monitoring center and also the field sensors. It collects the data from field sensors and controllers and then send them back to monitoring center. Its’s stable and reliable connection provide a trustable tunnel for the data communication and furthermore, then sensors like humidity, temperature, loading data etc are collected to remote SCADA System for further analysis. So this solution makes machines talking and with these kind of routine maintenance, believe the air compressor can have a longer lifecycle and continue to serve the industry.