NR500 Rugged Industrial Router for Gas Pipeline Monitoring

Overview

Customer specializes in Sales, Installation & Calibration Service of Instrumentation equipment in the Oil & Gas industry. Their services are tailored to match their customer’s specific needs, consistent with international standards and hands on approach to ensure prompt delivery and high level of customer satisfaction. They provide Process Control optimization via instrumentation and electrical engineering support, from the feasibility stage through to maintenance.

Challenge

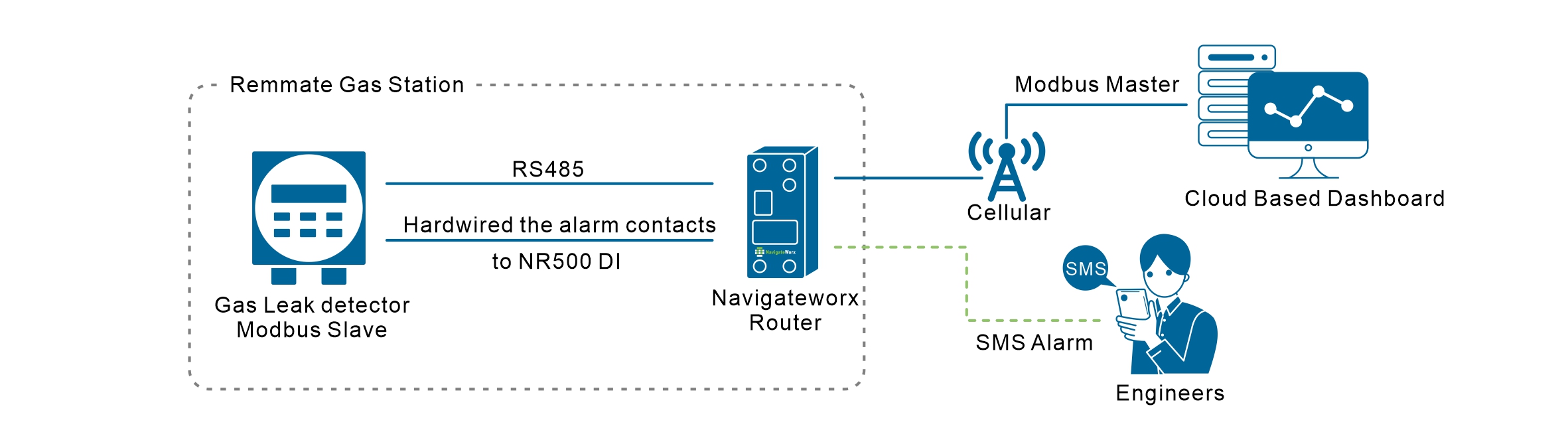

There is a HONEYWELL Sonik Gas Leak detector which is located on a Remote gas station on a Gas Pipeline in the Northern Territory. The Sonik is monitoring GOR (gas-oil ratio) gas leaks, which then will create an alarm. The Sonik is communicating by Modbus RTU protocol and need to send to cloud based dashboard via 4G Internet. Customer also need DI alarm trigger, when DI alarm occurs then 4G Router need to send SMS notifications to designated people.

Key needs for Gas Station:

• Robust Design: Work stable in harsh environment with strong humidity, high / low working temperature range.

• More Function: Modbus, DI triggers SMS alarm.

• Less Cost: Low project budget.

Solution

NR500 provides reliable low latency communications on 4G network, maintain the TCP connection for Modbus RTU convert to Modbus TCP. The information from the Sonik is transmitted via Modbus RTU to NR500 Pro, then NR500 is transmitting via 4G connection to the Internet, where they are hosting a cloud-based dashboard, so the customer can see the Sonik values, alarm status and other information. The dashboard will send emails to designated people. Customer also hardwired the alarm contacts from the Sonik, to the DI on NR500. If an alarm occurs the modem sends SMS to designated people.

Solution Advantage

- Saving Costs

NavigateWorx's NR500 helps engineers monitor real-time operation of the machines, response to faults with shortened time, and plan for preventive maintenance, saving both manpower and costs significantly.

- Multiple Industrial Interface for Machines

NR500 has 4 x Ethernet ports, 1 x RS232 and 1 x RS485 interfaces supports Serial to IP communication. 2 x Digital Input and 2 x Digital Output for the connection of Sensors and Actuators.

- Reliable Network Communication

The NR500 provides reliable low latency communications between machines and the center. Multiple interfaces failover and Dual SIMs capabilities for redundancy between cabled landline and mobile operator or between different 4G mobile data carriers.

- Working In Harsh Environment

With NR500, now it’s flexible enough with its strong and high EMC level design, it could get all equipment connected and have internet access to be online for remote visitors all the time.

Customer Feedback

I am extremely impressed with the support provided by your engineer, it is so good to know a manufacturer that stands by and support their product like this. I will continue to find opportunities for NR300 and NR500.