NR500 Ensure Compressors with Continuous Monitoring

Overview

Air compressors are widely used for purposes that include supplying air-driven equipment in production lines and are said to account for approximately 30% of power consumption at a typical manufacturing plant. As the use of air compressors varies depending on a factory’s production process, and because their efficient operation can reduce energy consumption, there is rising demand for remote monitoring to support efficient operation through appropriate maintenance.

Challenge

Traditional Air Compressor Remote Monitoring and maintenance methods can lead to higher downtime of air compressors. These assets need to work round the clock to generate desirable production volumes. A solution leveraging the power of Industrial IoT 4.0, cloud and data analytics will be very helpful to avoid manual maintenance and improve the bottom line.

Key needs for Digital Signage:

• Robust Design: Work stable in harsh environment with strong humidity, high / low working temperature range.

• Less Cost: Avoid high cost of wired-based console networking solutions, such as ADSL and fiber optics, and offer more flexible wireless network

• Better Service: Provide Dual Simcards fail-over policy in order to be reliable in real deployment applications.

Solution

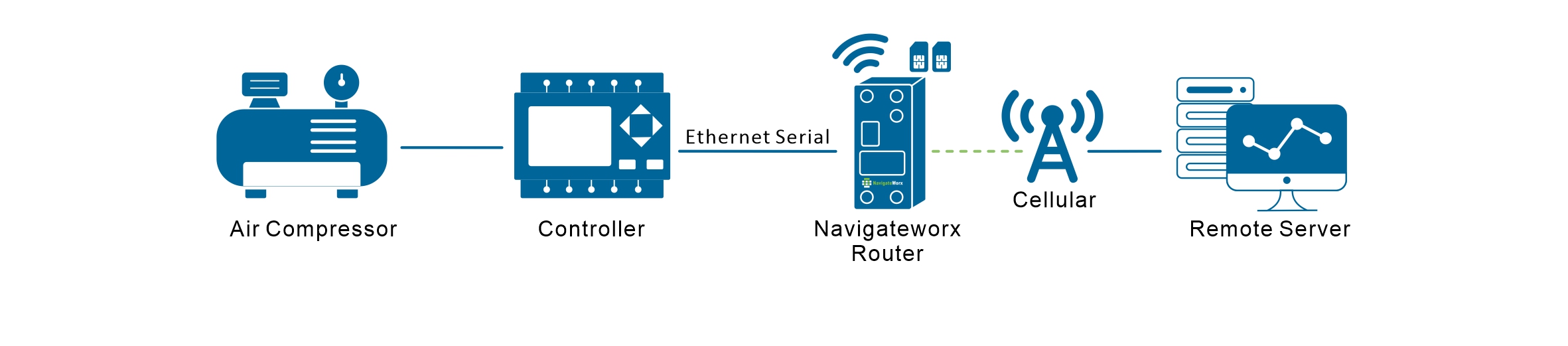

Air compressor remote monitoring solution easily connects to the field air compressor using our state-of-art-IoT-technology. NavigateWorx router connect with controller and provides the reliable connection between the remote monitoring center and the field air compressors. All the telemetry data is captured (including air pressure, temperature, CFM, motor power, oil level and a number of other relevant telemetry for specific air compressor types) and transmitted through NavigateWorx router to remote center for analysis and is presented to web and mobile platform for easy and quick decision making. And if there is any alert signal coming, the technicians could be noticed to diagnose and address the problem.

Solution Advantage

- Working In Industrial-grade construction

NavigateWorx Routers are designed to comply real industrial grade standards and offer ruggedized solution, capable of withstanding a number of extreme environmental conditions.

- Reliable Network Communication

NavigateWorx Routers provides reliable compelling connectivity option between air compressor and the Remote Center. Routers support Dual Sim Card failover policy to maintain session persistence.

- Flexible Industrial Interfaces and protocols

NavigateWorx Routers has rich connection interfaces with incorporating flexible protocols for data communication.

Customer Feedback

- Pre:None