NR300 Ensuring Remote Machines Run Smoothly

Overview

In recent years, Industry 4.0 had become one of the hottest topics in our daily life and with the development of IIoT / M2M, more and more things are connected via advanced technologies and getting it closer and closer to Industrial 4.0 applications. The idea is to get tens / hundreds of machines well connected from each corner of the world and make it easier to remote access to the machines and do the configuration. This idea is very attractive to the manufactures because Machine Monitoring can be a quick win and they can connect every machine and/or resource to see and understand how each machine is performing, and start to generate accurate, timely and relevant analysis data. This is the real application of Industrial 4.0 and it benefit us a lot.

Challenge

Remote Machine Monitoring Systems is a perfect fit for manufacturers who are looking to enhance reliable communication, improve efficiency, and embrace data-driven smart manufacturing. They need the system very simple to integrate, easy to use, and produces powerful results. They also need to know how collect data automatically from any machine or process, identify and stop all areas of downtime to monitor and optimize their production with confidence.

Key needs for Digital Signage:

• Robust Design: Work stable in harsh environment with strong humidity, high / low working temperature range.

• Less Cost: Avoid high cost of wired-based console networking solutions, such as ADSL and fiber optics, and offer more flexible wireless network

• Better Service: Provide various interfaces in order to be flexible in real deployment applications.

Solution

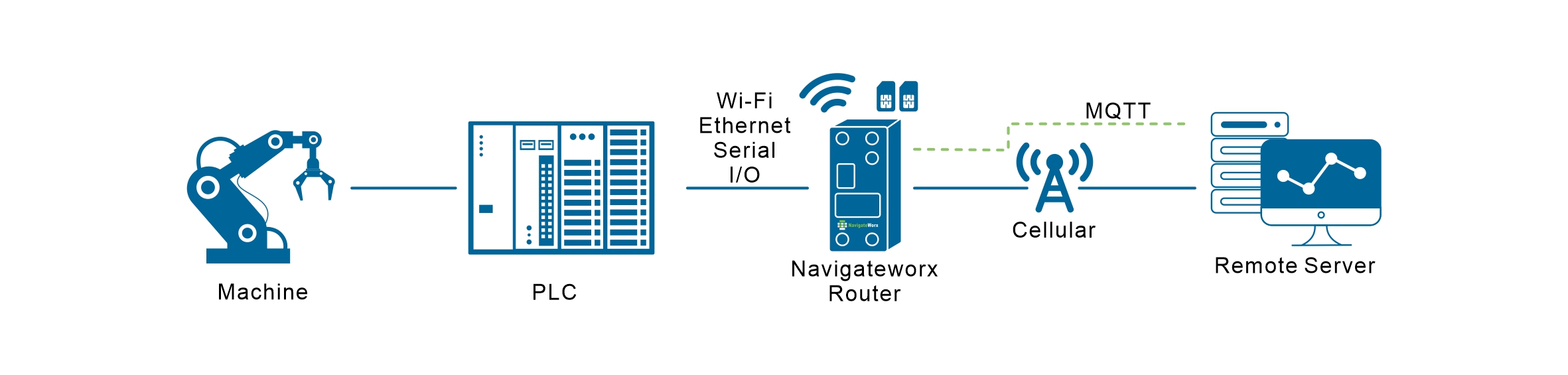

NavigateWorx router is selected for this kind of application. With its Robust performance and high EMC level design, it could get all the machines well connected and have flexible internet access to be online for remote visitors (business owners, engineering or maintenance managers, facility or operations supervisors and others) all the time. Abundant interfaces provide the connection for the local PLC via Serial, Ethernet Ports or DI/DO, and NavigateWorx router could transfer data from Modbus to MQTT protocol, and send to remote center. This Solution improve operational efficiency by understanding performance down to the individual resource and maximize the utilization of production resources and base decisions for investment on real data.

Solution Advantage

- Working In Industrial-grade construction

NavigateWorx Routers are designed to comply real industrial grade standards and offer ruggedized solution, capable of withstanding a number of extreme environmental conditions.

- Reliable Network Communication

NavigateWorx Routers provides reliable compelling connectivity option between PLC and the Remote Center. Routers support Dual Sim Card failover policy to maintain session persistence.

- Flexible Industrial Interfaces and protocols

NavigateWorx Routers has rich connection interfaces with incorporating flexible protocols for data communication.