NR500: Guardian of CNC Machine Operations

Overview

In the age of Industrial IoT, manufacturers who realize the benefits of smart technology will stay a step ahead of the competition in an ever-competitive landscape. When you’ve got production targets to meet and the challenge of keeping costs under control, it’s essential to have a true and accurate picture of your manufacturing resource activity. With the involvement of CNC Machines, Production Line become efficient and automatic. Thanks to 24 / 7 Guardian, CNC Machines Remote Monitoring helps build greater integrity into the measurement of manufacturers’ resource activity and performance.

Challenge

For manufacturers, installing CNC Machine Monitoring Systems is that first and most important step to harness, structure, and take action on production data. They need bring smart manufacturing to the factory floor that’s simple to integrate, easy to use, and produces powerful results. They also need to know how collect data automatically from any machine or process, identify and stop all areas of downtime to monitor and optimize their production with confidence.

Key needs for Digital Signage:

• Robust Design: Work stable in harsh environment with strong humidity, high / low working temperature range.

• Less Cost: Avoid high cost of wired-based console networking solutions, such as ADSL and fiber optics, and offer more flexible wireless network.

• Better Service: Provide various interfaces in order to be flexible in real deployment applications.

Solution

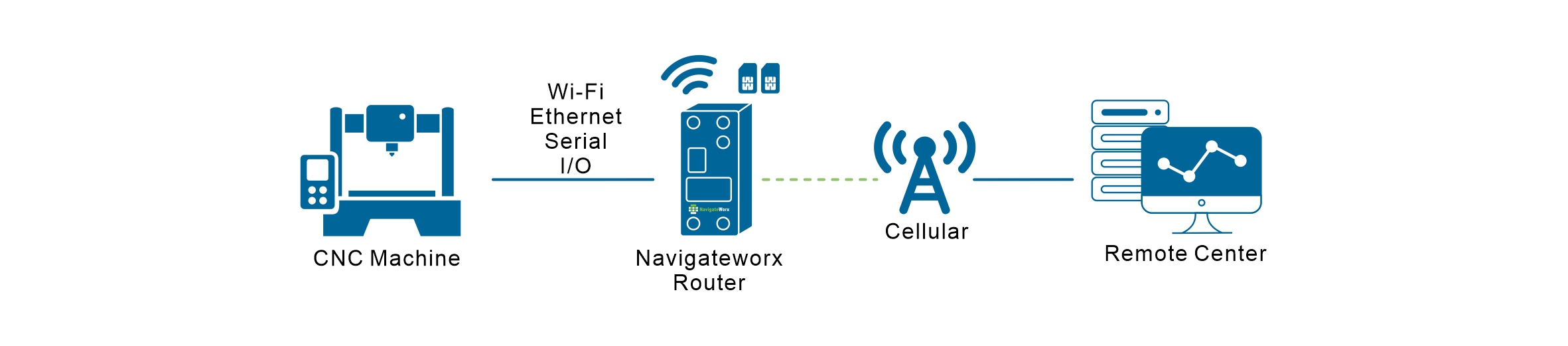

NavigateWorx router is suitable for this kind of application. Thanks to its very high EMC Level design and also Dual SIM Backup design makes it be able to work continually 24 / 7. NavigateWorx router offer various interfaces including Ethernet ports, Serial port, DI/Dos for flexible connection with different CNC machines in different manufacturing plants. The data from CNC machines could be collected as Modbus protocol and transmitted to NavigateWorx router, then router could transfer to MQTT protocol, and send to remote center. The solution makes manufactures get real-time monitoring, track energy and resource usage as it happens, usage optimization, identify wastage, improve efficiency, and reduce costs, which make decisions that are good for your business and great for the planet.

Solution Advantage

- Working In Industrial-grade construction

NavigateWorx Routers are designed to comply real industrial grade standards and offer ruggedized solution, capable of withstanding a number of extreme environmental conditions.

- Reliable Network Communication

NavigateWorx Routers provides reliable compelling connectivity option between CNC Machines and the Remote Center. Routers support Dual Sim Card failover policy to maintain session persistence.

- Flexible Industrial Interfaces and protocols

NavigateWorx Routers has rich connection interfaces with incorporating flexible protocols for data communication.