NR300: Safeguarding Remote Package Machines

Overview

Packaging is an essential segment of any business. The demand for packaging has been rising exponentially with respect to the interesting design and quality of the packaging, which have a significant impact on a product’s success or failure in the market. Today’s expanding retail outlets such as supermarkets, supercenters, convenience stores, and others are all creating a variety of marketing challenges and new opportunities for innovative packaging introductions. Further, the cutthroat competition from the e-retail sector is also driving the demand for an innovative packaging solution to attract customers, thereby buoying the need for advanced packaging machinery.

Challenge

In the current era of the high demand for various products, the packaging of the products is done on high throughput and high-speed machinery. These machines are designed to prepare different sizes of packages as per the product requirements. Smart Packaging Machines Remote Monitoring- Challenges and Drivers Implementation of smart packaging machines supports the end users to increase their packaging operations and addresses the business needs in several ways.

Key needs for Digital Signage:

• Robust Design: Work stable in harsh environment with strong humidity, high / low working temperature range.

• Less Cost: Avoid high cost of wired-based console networking solutions, such as ADSL and fiber optics, and offer more flexible wireless network.

• Better Service: Provide reliable data transmission in order to be monitor remote PLC in real time.

Solution

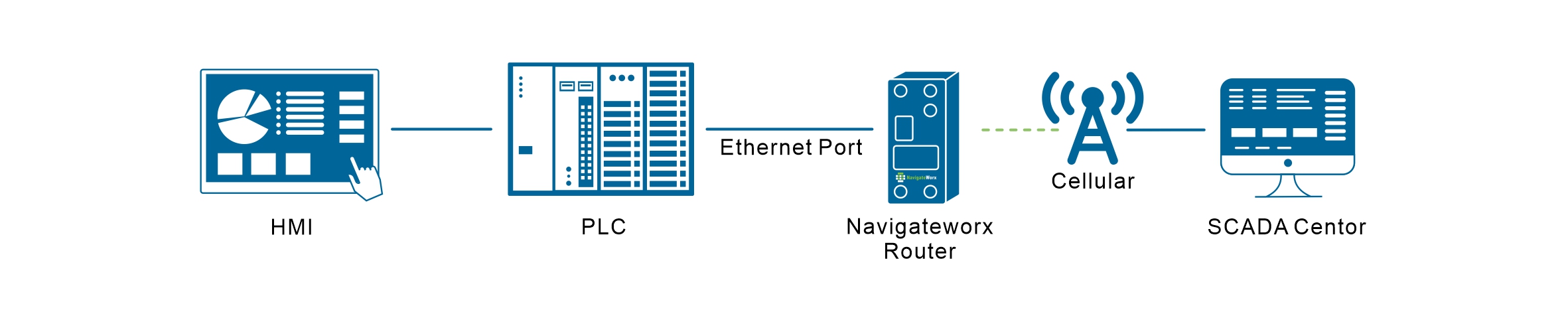

The project for remote monitoring package machine aims offering an implementation of a human machine interface (HMI) for a programmable logic controller (PLC) based automated packaging process that can be remotely controlled and monitored through SCADA Centor. A conveyor belt does the moving of products to a destined place for packaging, is controlled by a PLC. An HMI is designed with an android application and the microcontroller (as the processor) that establish a communication path between the engineers and PLC based plant. The interface provides remote controlling and monitoring feature, which enable to minimiz the overall cost by replacing the widely used supervisory control and SCADA system. The performance of the implemented prototype is evaluated through several real-time operations, which shows satisfactory results.

NavigateWorx router is selected for this application and its fully industrial design makes sure that all the data are transferred in real time. More importantly, our abundant interfaces all users to get all the equipment well connected so that they don’t need to use an extra simple fast Ethernet switches, that’s more cost effective solution for the applications.

Solution Advantage

- Working In Industrial-grade construction

NavigateWorx Routers are designed to comply real industrial grade standards and offer ruggedized solution, capable of withstanding a number of extreme environmental conditions.

- Reliable Network Communication

NavigateWorx Routers provides reliable compelling connectivity option between PLC and the monitoring SCADA Center. Routers support Dual Sim Card failover policy to maintain session persistence.

- Flexible Industrial Interfaces and protocols

NavigateWorx Routers has rich connection interfaces with incorporating flexible protocols for data communication.

Customer Feedback

- Next:None